The floating fish feed production line has a high degree of automation, high labor efficiency, and large output, which can reduce labor costs. The production capacity of the fish feed production line we provide is 500-2000kg/h, and different plans can be made according to the customer’s production capacity needs. The floating fish feed production line we provide is very suitable for aquaculture and large and medium-sized feed factories.

Introduction of Floating Fish Feed Production Line

A complete floating fish feed production line is usually composed of multiple production links, mainly including raw material preparation, crushing, mixing, extrusion, drying, cooling and other steps. The entire production line adopts automated equipment and control systems, with a high degree of automation and does not require a lot of manpower, so the production efficiency and product quality are good.

Components of Complete Fish Feed Production Line

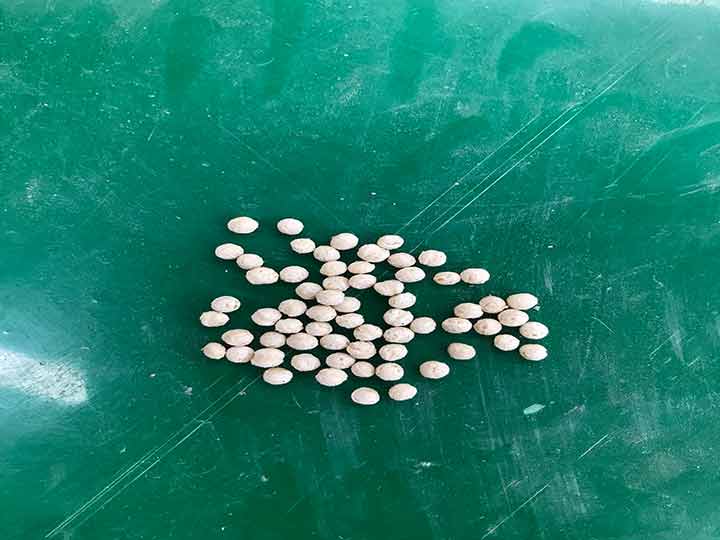

A complete fish feed production line consists of multiple production steps. The main equipment includes crusher, mixer, extruder, dryers, coolers and packaging machines. Fish feed production lines can produce feeds required by aquatic animals at different stages, and can also be used for aquatic animals such as young fish and shrimp. The scope of application is particularly wide. The following is the working process of floating fish feed production line:

Advantages of Flotation Fish Feed Production Line for Producing Feed

- Large-scale production: The fish feed production line adopts automated equipment, which can work continuously, improve production efficiency and reduce labor costs.

- High-quality feed: In the process of producing feed, strict quality control and production standards can be implemented to ensure the stable and reliable quality of feed products.

- Environmental protection and energy saving: The feed production line we provide adopts advanced production technology and environmental protection facilities to reduce waste and emissions, which is more energy-saving and environmentally friendly and protects the environment.

- Adapt to market demand: The aquatic feed production line can flexibly adjust the production line according to market demand to produce different types of aquatic feed.

- Improve competitiveness: The production advantages of large-scale, high efficiency and stable quality can improve the competitiveness of fisheries or feed mills in the market and meet customer needs.

Conclusion

The complete fish feed production line is more complicated than the simple fish feed production line, but it is easy to operate, has a high degree of automation, high production efficiency, high nutritional value of the produced feed, and high competitiveness. If you are interested in our 500-2000 kg fish feed production line, please contact us!

Technical Parameters

| Capacity:500-2000kg/h | Process flow:1.bucket elevator -2.buffer bin -3.hammer mill -4.bucket elevator. -5.buffer bin -6.mixer -7.bucket elevator -8.Broken arch bin -9.wet way feed pellet extruder -10.air conveyor -11.dryer -12.air conveyor -13.seasoning machine -14.air conveyor -15.cooler -16. air conveyor -17. finished product silo |

| Power: 94-217kw | Size for whole line: 30×6×7m |

| Range of application: Good for medium/big commercial Aquatic / pets feed factory | Workers requirements: 2-3 people |

| Product advantage: Long working life, make high protein feed , Stable output, high efficiency, continuous work, labor saving, can pack directly,pellet size could be chosen from 1-12mm | Shipment requirements: 2×40ft container |