Fish feed extruders can be divided into two types: dry fish feed extruders and wet fish feed extruders. Wet fish feed extruders can produce both floating fish feed and sinking fish feed. The formula needs to be adjusted during production to meet customers’ different needs for fish feed. Wet fish feed extruders produce fish feed with higher output and better quality. It is very suitable for large and medium-sized feed processing plants, fish farms, etc. Many customers like this wet fish feed extruder very much.

Introduction of Wet Type Fish Feed Extruder

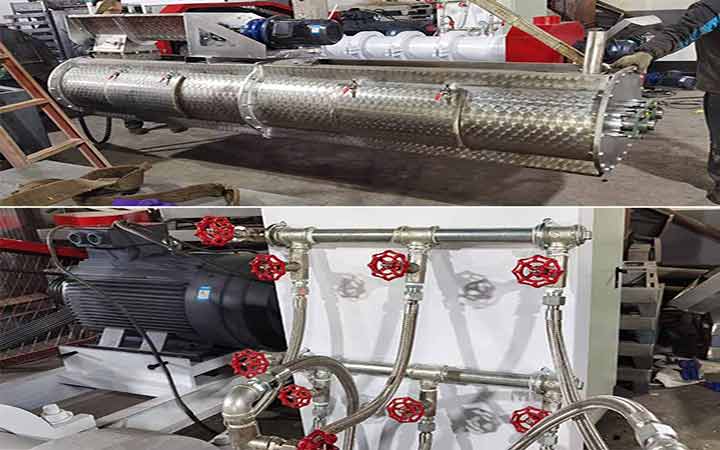

Wet fish feed extruder can generate steam in the process of producing fish feed. Therefore, the fish feed produced by wet fish feed extruder is of better quality and has higher nutritional value. The wet fish feed extruder we provide adopts advanced technology and is not complicated and easy to operate. Wet fish feed extruder is also widely used in fish feed production lines to produce fish feed pellets, which is very popular with customers.

Application of Wet Fish Feed Extruder

Wet fish feed extruder is mainly applied to produce aquatic feeds such as fish, shrimp, crab, loach, etc. At the same time, the extruder can also produce pet feed such as cats and dogs. The size of the fish feed particles produced by the wet fish feed extruder can be adjusted according to needs, and it can also be used to raise small fish, shrimp and other aquatic animals. The feed produced by the wet fish feed extruder is more nutritious, which can provide higher nutritional value to fish and promote the healthy growth of fish.

What is a Wet Type Fish Feed Extruder?

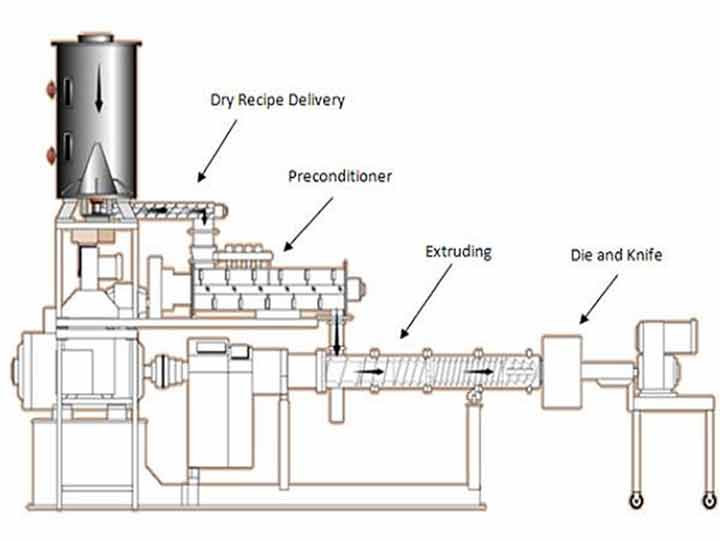

The wet type fish feed extruder can process feed materials with higher humidity. Its working process is different from that of the dry type fish feed extruder and its structure is more complicated. The following is the production process of the wet type fish feed extruder:

- Prepare raw materials: First, we need to prepare the raw materials, and then put the raw materials into the feed port according to the formula ratio.

- Mixing: The feed raw materials will be evenly mixed after entering the feed port. The mixing effect of the extruder we provide is particularly good, the various components in the feed raw materials can be evenly distributed, and the working efficiency is high.

- Add water: Add an appropriate amount of water to the mixed raw materials and stir them fully to form moist fish feed raw materials.

- Extrusion molding: The fish feed raw materials are sent into the extrusion area of the extruder. Through the action of the extrusion mold, the fish feed raw materials can be extruded into fish feed particles of a fixed shape.

- Cutting: The extruded fish feed particles will be cut by the cutting device to cut the fish feed into fish feed particles of a certain size, which is more convenient for fish to eat and digest.

- Packaging: After drying and cooling, the formed fish feed particles can be packaged to extend the shelf life of the fish feed and facilitate transportation to the fish farm or the place where the fish feed is needed.

Advantages of Wet Fish Feed Extruder for Making Fish Feed

- High-quality fish feed: The fish feed pellets produced by the wet fish feed extruder are more uniform and delicate, with good taste and higher nutritional value, which is beneficial to fish digestion and utilization of fish feed.

- High work efficiency: The wet fish feed extruder has a high degree of automation, saves manpower, can carry out continuous work, and reduce production costs.

- Improve the stability and shelf life of the feed: The feed pellets produced by the wet fish feed extruder have high density and strong water resistance, which can reduce the possibility of pellet oxidation and extend the shelf life of the feed.

- Reduce the use of additives: The fish feed pellets produced by the wet fish feed extruder are more solid and firm, reducing the use of additives.

Maintenance of Wet Fish Feed Extruder

Regular inspection and maintenance of wet type fish feed extruders are very important, which can keep the equipment running normally and extend its service life. The following are suggestions for fish feed extruder maintenance:

- Regular cleaning: After a long period of use, the extruder should be cleaned regularly to ensure that the internal parts of the equipment are clean and avoid damage to the equipment caused by deposited impurities.

- Daily routine maintenance: According to the use of the extruder, routine maintenance work should be carried out to check whether the screws are loose and whether the equipment is worn.

- Regular lubrication and maintenance: Regularly check whether the lubricating oil is sufficient, add or replace the lubricating oil in time to ensure the normal operation of the parts inside the extruder.

- LearnLearn and understand the operation manual: Learn the operation manual of the extruder, strictly follow the operation steps of the equipment, understand the working principle and maintenance methods of the equipment, and solve problems in time. and understand the operation manual: Learn the operation manual of the extruder, strictly follow the operation steps of the equipment, understand the working principle and maintenance methods of the equipment, and solve problems in time.

- Safe operation: Pay attention to safe operation when using the extruder to avoid damage to the equipment or personal injury due to improper operation.

Conclusion

Wet fish feed extruder is one of the important equipment for making fish feed, and can also be applied to fish feed production line. Wet fish feed extruder can improve feed quality, save costs and improve production efficiency when processing feed raw materials with high humidity, so it has certain advantages in fish farming feed processing. If you are interested in wet fish feed extruder, please contact us!

Technical Parameters

| Model | Capacity (kg/h) | Main motor (kw) | Feeder motor (kw) | Screw diameter (mm) | Cutter motor (kw) | Conditioner (kw) | Machine size (mm) | Weight (kg) |

| LM60SD | 180-200 | 15 | 1.5 | Φ60 | 1.1 | 2.2 | 1780×1250×1300 | 480 |

| LM70SD | 250-300 | 18.5 | 1.5 | Φ70 | 1.1 | 2.2 | 2460×1550×1740 | 940 |

| LM80SD | 300-400 | 22 | 1.5 | Φ80 | 1.1 | 2.2 | 2650×1450×1750 | 1000 |

| LM90SD | 500-600 | 37 | 1.5 | Φ90 | 1.1 | 2.2 | 2600×2100×1900 | 2000 |

| LM120SD | 700-800 | 55 | 1.5 | Φ120 | 1.5 | 3 | 3200×1950×1900 | 2200 |

| LM135SD | 1000-1200 | 75 | 1.5 | Φ133 | 2.2 | 3 | 3570×1980×1800 | 2500 |

| LM145SD | 2500-3000 | 110 | 1.5 | Φ135 | 4 | 7.5 | 6600×2800×2330 | 3800 |