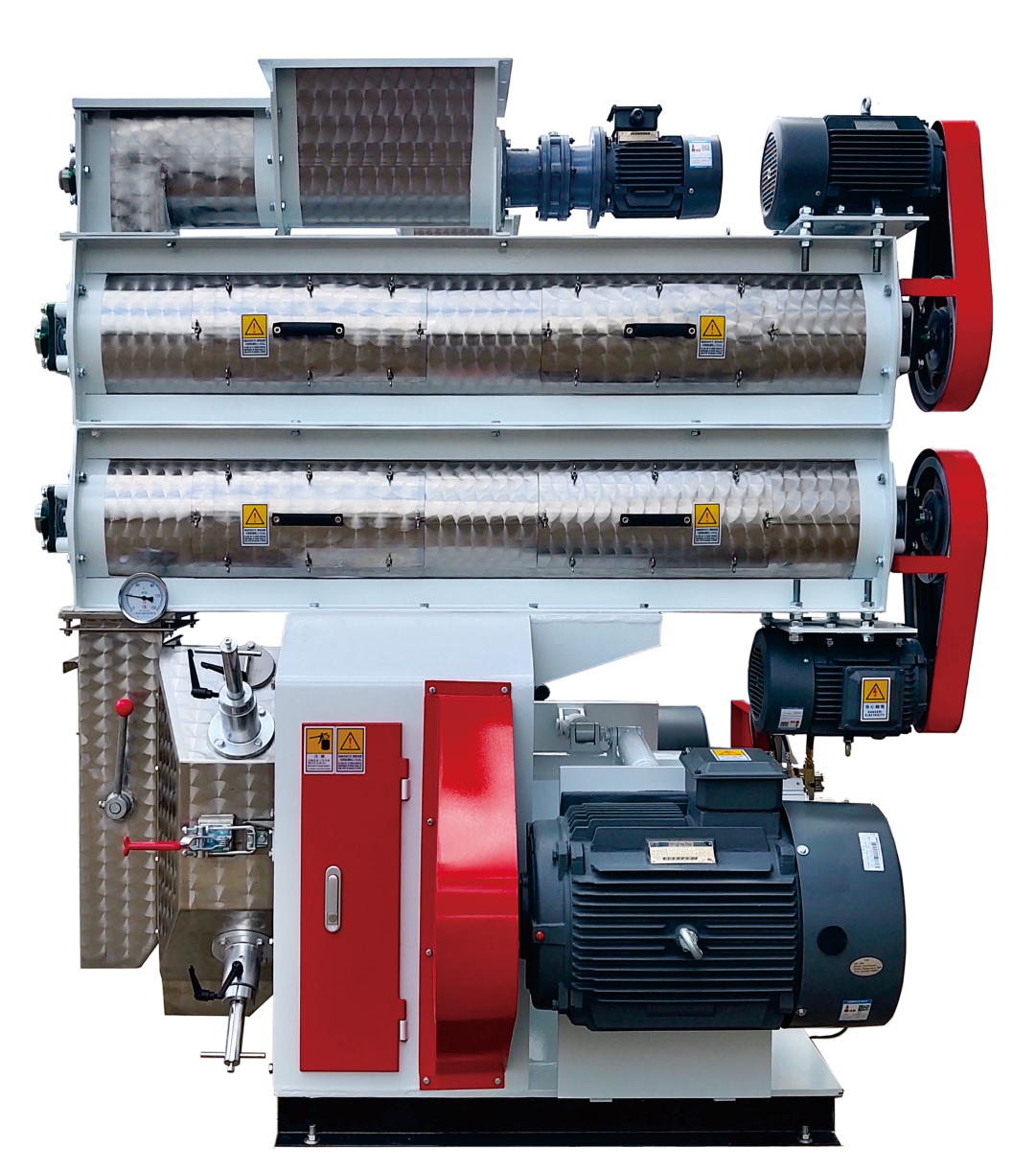

Ring die poultry feed making machine uses a stainless steel modulator and is widely used in the production of animal feed pellets. It can not only produce poultry feed pellets such as chickens, ducks, geese, but also livestock feed pellets such as cattle and sheep, etc. The output of the ring die poultry feed making machine is relatively large, more than 1 ton/h, and is generally used with a production line.

What is the ring die poultry feed making machine

Ring die poultry feed making machine adopts stainless steel modulator, which is a feed processing machine that directly presses crushed corn, soybean meal, straw, grass, rice husk, etc. into feed pellets. It is widely used in large, medium and small aquaculture, grain feed processing plants, livestock and poultry farms, individual breeders and small and medium-sized farms, breeders or large, medium and small feed processing plants. Ring die poultry feed making machine is the main feed machinery equipment for producing pellet feed. Compared with flat die poultry feed making machine, it has more comprehensive performance, larger output and higher price, and occupies a very important position in the feed processing process.

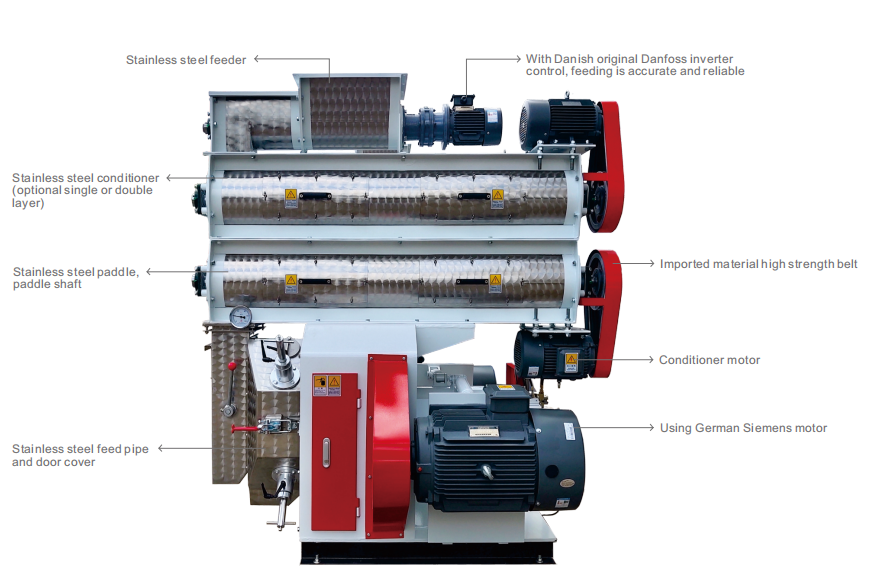

Details of ring die poultry feed making machine

As shown in the picture, a ring die poultry feed making machine contains, stainless steel feeder, motor, stainless steel conditioner, stainless steel feed pipe and door cover, conditioner motor and strength belt.

Model of ring die chicken feed making machine

| Model | Capacity (Ton/h) | Main power (kw) | Feeder power (kw) | Conditioner power (kw) | Machine size (mm) | Weight (kg) |

| SZLH250 | 1-2 | 22 | 0.75 | 1.1 | 1700×650×1750 | 715 |

| SZLH320 | 2-4 | 37 | 0.75 | 2.2 | 1800×1550×1650 | 1400 |

| SZLH350 | 2-6 | 55 | 0.75 | 2.2 | 2150×1950×1900 | 2000 |

| SZLH400 | 3-8 | 90 | 1.5 | 4 | 2300×2000×2020 | 2500 |

| SZLH420 | 4-12 | 110 | 1.5 | 4 | 2300×2330×2090 | 3200 |

| SZLH508 | 4-18 | 132 | 1.5 | 5.5 | 3350×2350×2200 | 4300 |

Features of ring die poultry feed making machine

- Efficient production: The ring die poultry feed making machine has efficient production capacity and is suitable for feed manufacturers with an annual output of 1-20 tons. It can significantly improve feed production efficiency.

- Wide adaptability: The ring die poultry feed making machine is suitable for processing a variety of materials and feeds. It can not only produce poultry feeds such as chickens, ducks and geese, but also animal feeds such as cattle, sheep, and pigs.

- High-quality pellets: The ring die poultry feed making machine uses extrusion molding to make pellet feeds with consistent specifications and good quality from raw materials.

- Improve nutrient absorption: During the pelleting process, the nutrients in the feed are fully mixed, which improves the digestion and absorption rate of the feed by livestock and poultry.

- High economic benefits: Compared with mixed powder feed, pellet feed can achieve higher economic benefits during the feeding process. It can not only improve the palatability of livestock and poultry, but also shorten the fattening period and reduce production costs.

- Environmental protection and energy saving: The ring die poultry feed making machine adopts advanced manufacturing technology and design concepts during the production process, reducing energy consumption and noise pollution.

- Easy operation: The ring die poultry feed making machine has a reasonable structure design and is easy to operate.

- Fast maintenance: The ring die poultry feed making machine has compact structure, beautiful appearance and easy maintenance. Key components such as the feeder, conditioner, and discharge chute are made of stainless steel and are durable.

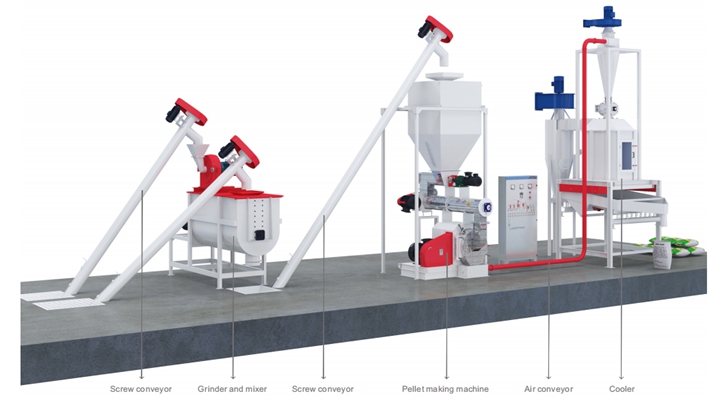

Ring die poultry feed making machine line

1-2ton/h ring die poultry feed making machine line-Design 1

| Capacity | 1-2ton/h |

| Power | 62.5kw |

| Range of application | Suitable for small/medium commerical feed factory,big farm |

| Product advantages | Stable output,high efficiency,continuous work,labor saving, can pack directly,pellet size could be chosen from 2-8mm |

| Process flow | 1.Conveyor -2.Crusher -3.Mixer -4.Screw conveyor -5.Feed pellet making machine -6.Air conveyor -7.Cooler -8.Screen |

| Size for whole line | 10×3×6m |

| Workers requirments | 2-3 people |

| Shipment requirments | 20ft container |

This is a tiled design, suitable for small/medium commerical feed factory,big farm. Stable output,high efficiency,continuous work,labor saving, pellet size could be chosen from 2-8mm. The produced feed pellets can be packaged directly.

Feedback of ring die poultry feed making machine line-Design 1

1-2ton/h ring die poultry feed making machine line-Design 2

| Capacity | 1-2ton/h |

| Power | 68.5kw |

| Range of application | Suitable for small/medium commerical feed factory,big farm |

| Product advantages | Stable output,high efficiency,continuous work,labor saving,make crumble feed,automatic package,pellet size could be chosen from 2-8mm |

| Process flow | 1.Conveyor -2.Crusher -3.Mixer -4.Screw conveyor -5.Feed pellet making machine -6.Air conveyor -7.Cooler -8.Crumbler -9.Bucket elevator -10.Vibrating screen -11.Finished product silo -12.Automatic packing machine |

| Size for whole line | 12×4×9m |

| Workers requirments | 2-3 people |

| Shipment requirments | 40ft container |

This design adopts a three-layer design, which saves the customer’s factory space and is suitable for customers whose factories have no restrictions on floor height.

Video of ring die poultry feed making machine line-Design 2

Other design of ring die poultry feed making machine line

This design compresses the volume of the entire ring mold production line to a minimum, and is suitable for customers whose factories are not very large but still want large output.

Summarize of ring die poultry feed making machine

Ring die poultry feed making machine is a feed pellet machine with stable performance, strong adaptability and wide application. Because of its large output, it is generally used with production lines. Lima has customized ring die production lines for hundreds of customers over the years, providing customers with their own exclusive feed production solutions. If your factory or farm also needs to produce feed, please contact us.