With the development of aquaculture, fish feed is used more and more widely, and many fish farms or feed factories use fish feed. A floating fish feed extruder is an important equipment for making fish feed, which can press the feed into various shapes of fish feed. Fish feed extruders can be divided into dry type fish feed extruders and wet type fish feed extruders.

Application of Floating Fish Feed Extruder

The application of the floating fish feed extruder is very wide. It can produce aquatic animal feed, including freshwater fish and marine fish, and pet feed, such as pet cats, dogs, etc. The extruder can produce fish feed of different sizes to meet the feed needs of various types of fish in different growth environments and different growth stages. The floating fish feed extruder can produce flotation fish feed and sinking fish feed. Flotation fish feed is convenient for fish to eat and digest, and sinking fish feed is conducive to the feeding of fish below.

Types of Floating Fish Feed Extruders

Fish feed extruders can be divided into dry type fish feed extruders and wet type fish feed extruders. Dry fish feed extruders mainly process feed raw materials with low moisture content and extrude dry raw materials into granules. Wet fish feed extruders can process feed raw materials with high moisture content and can make feed raw materials with high moisture content into granules by mixing and extruding.

Based on the power of the extruder, fish feed extruders can be divided into electric extruders and diesel extruders. Electric fish feed extruders are mainly powered by electric motors and are usually connected to a power source. They are relatively environmentally friendly and have less noise. Diesel fish feed extruders mainly use diesel as fuel to provide power for areas without power supply.

Working Process of Floating Fish Feed Extruder

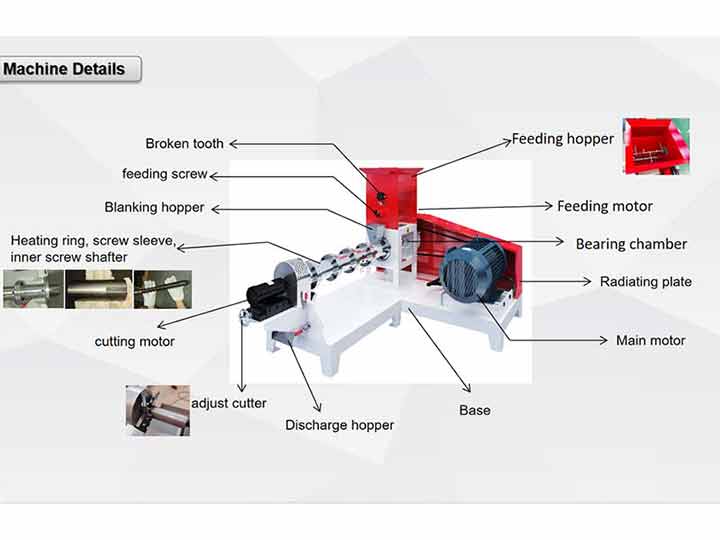

Detailed Floating Fish Feed Extruder

Detailed Features of Floating Fish Feed Extruder

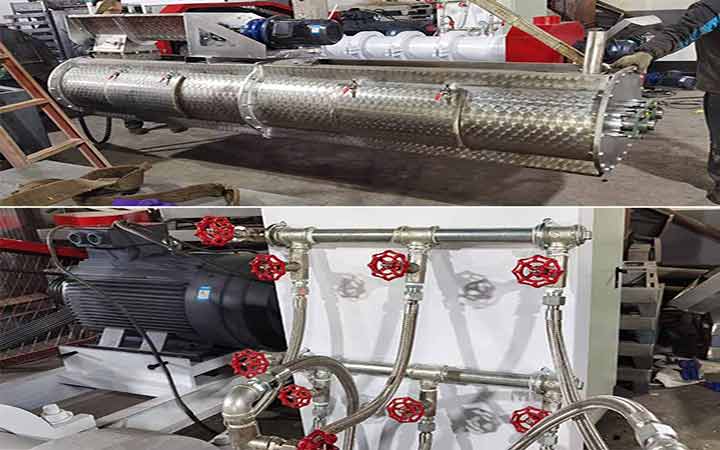

- Design structure: The floating fish feed extruder adopts a special design structure, including the feed inlet, extrusion screw, mold and discharge port. Ensure that the feed can obtain uniform pressure and temperature during the extrusion process to ensure the quality of the produced feed.

- High efficiency: The fish feed extruder has high working efficiency and can quickly and evenly extrude the raw materials into the required granular state.

- Adjustability: The fish feed extruder has the function of adjustment, which can adjust parameters such as pressure and temperature to meet the processing requirements of different types of feed and produce feed that meets the requirements.

- High safety of the extruder: The operation of the fish feed extruder is simple. During the operation, pay attention to safety, reduce the occurrence of failures, and ensure the safe operation of the machine.

Conclusion

The floating fish feed extruder plays a key role in the production process of fish feed. The fish feed extruder we provide has high working efficiency and long service life and can produce feed pellets required by fish at different stages. If you are interested in our flotation fish feed extruder, please contact us!