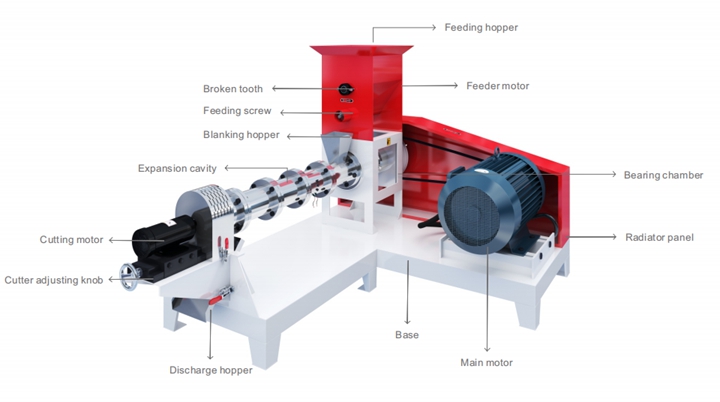

A fish feed extruder mainly consists of a pelletizing part, a feeding part and cutter part. The pelletizing part mainly includes a motor, a screw, a screw sleeve, a mold, etc. The feeding part includes a feeding motor, a feeding hopper, etc. The rest includes a base and control box, etc.

Fish feed extruder details

Feeding part of fish feed extruder

The feeding part consists of a feeding hopper, a feeding motor and broken tooth.

When the fish feed extruder is running, the crushed raw materials are poured into the feeding hopper. The broken tooth in the feeding hopper will continuously stir the raw materials driven by the feeding motor to prevent the raw materials from agglomerating and improve the machine’s operating efficiency.

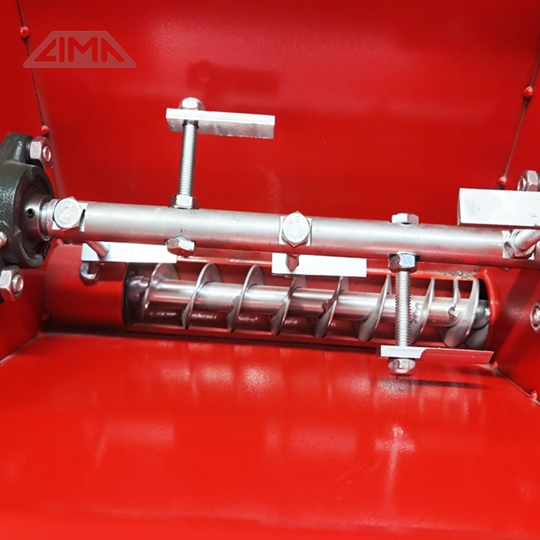

Pelletizing part of fish feed extruder

The pelletizing part includes the main motor, screw, screw sleeve and mold.

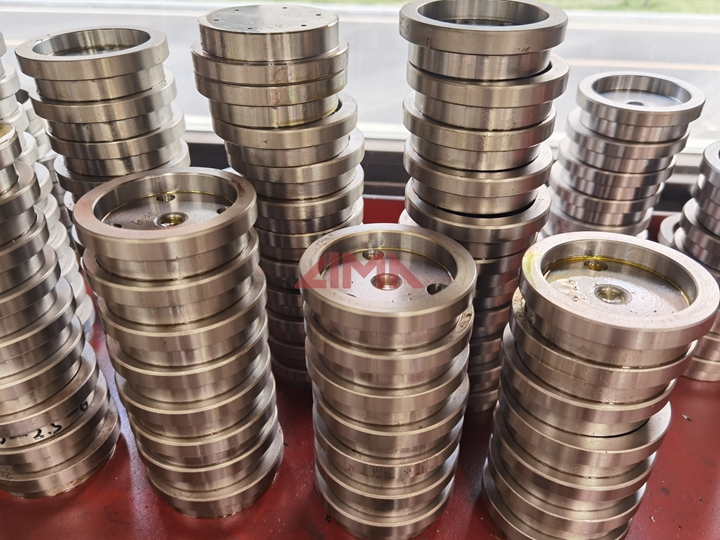

The fish feed extruder uses a belt drive. The main motor drives the belt to rotate and the screw to rotate. Under the rotation and extrusion of the screw, the material will come out through the mold at the front end of the extruder machine. Different sizes of molds can produce feed particles of different sizes, suitable for fish at different growth stages.

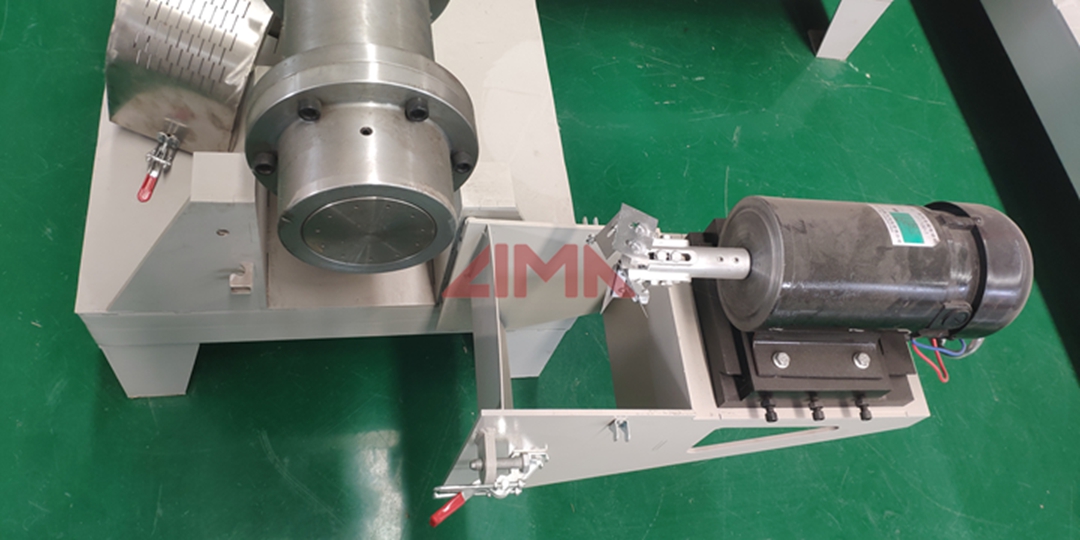

Cutter part of fish feed extruder

The cutter part includes the cutter, cutter motor and Cutter protection cover.

When the material comes out of the mold, the cutter, driven by the cutter motor, will finally make the material into particles. The cutter protection cover will protect people from getting close to the machine when it is running, which will cause harm to people. Of course, the cutter is a consumable part and needs to be replaced regularly.

Other parts of fish feed extruder

Base and control box