With the development of science and technology, mechanized breeding is a more popular breeding mode. Mechanized breeding is more efficient and practical, and the breeding machinery and equipment for making feed are also very simple to operate. Farmers can make feed pellets at home. This article mainly helps farmers how to make feed pellets with high nutritional value at home efficiently.

Preparing Raw Materials

Before making poultry feed, we need to prepare the raw materials needed. Poultry feed should be nutritious, containing nutrients such as protein, vitamins and minerals. Therefore, we must choose the feed raw materials to ensure the safety and reliability of the raw materials. We can choose grains such as corn, wheat and soybean meal as raw materials. We can mix the prepared raw materials according to the formula ratio and pour them into the feed machine.

How to Use Poultry Feed Pellet Machine at Home

Before using the poultry feed machine, we need to check whether the feed machine is clean and adjusted. We need to determine the required feed raw materials and formula ratio. Adjust the size of the feed machine particles, pressure and other parameters as needed. Introduce the prepared feed raw materials into the feed machine. In the process of making feed, gradually add feed raw materials as needed, and adjust the parameters of the feed machine at the same time. Finally, collect the prepared feed particles from the discharge port for cooling or storage. The production of feed particles has been completed. We must pay attention to safety in the process of making feed, find abnormal conditions, and deal with them in time.

Poultry Feed Production Line Process

The process of poultry feed production is not complicated, and farmers can quickly master how to use poultry feed production equipment. What equipment does the poultry feed production line mainly include, and how to produce poultry feed at home. The following are the main steps in the production of poultry feed pellets:

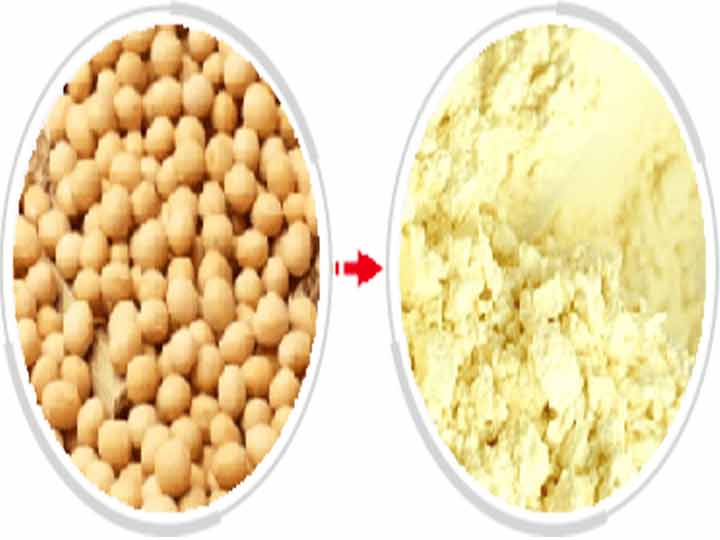

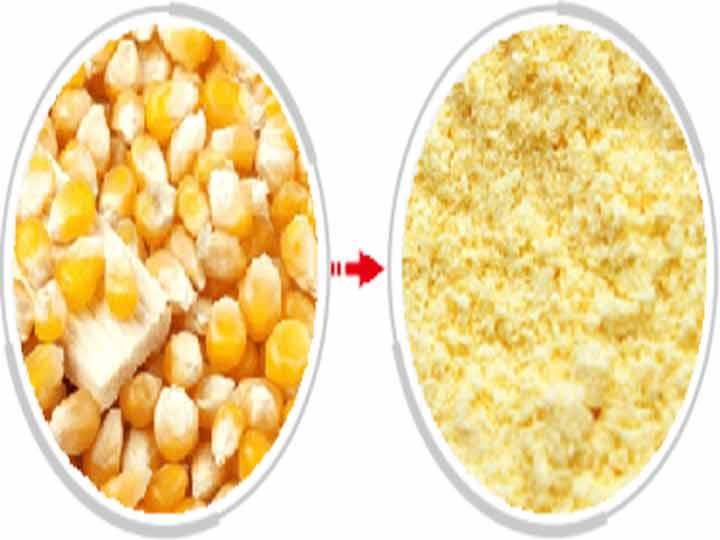

Grinding and crushing: We need to grind various raw materials and crush larger feed raw materials into the powder state required by poultry animals. It facilitates pressure molding in the subsequent production process.

Mixing and stirring: The crushed raw materials are conveyed into the mixer through the screw. Various feed raw materials are evenly mixed by mixing and stirring inside the mixer, so that the nutrients in the raw materials are evenly distributed.

Pellet forming: The mixed raw materials are fed into the pellet machine through a screw, and the raw materials are transformed into pellets under high temperature and high pressure. The pellet machine we provide can adjust the size of feed pellets, and it is also very simple and convenient to replace the mold.

Cooling and packaging: The prepared feed pellets are cooled and stored conveniently. The cooled feed can be packaged and can be bagged and transported to where it is needed.

Advantages of Making Feed at Home

- Cost savings: Making feed at home can reduce the cost of purchasing commercial feed. The poultry feed production line is highly automated and does not require a lot of manpower, which can reduce labor costs.

- Customized feed formula: Make feed at home, and adjust the feed formula at any time according to the growth and nutritional needs of poultry. Produce feed that is more suitable for poultry needs.

- Adjust feed production: Making feed at home allows you to adjust the formula and quantity at any time according to the actual needs and consumption of poultry, and respond more flexibly to different situations.

- Control feed quality: When making feed at home, the raw materials of feed can be strictly inspected to ensure the safety of feed. This can produce higher quality feed.

How to Repair and Maintain Feed Machines at Home

- Cleaning and maintenance: After we use the feed machine, we must clean it in time. The feeder avoids the accumulation of residue and dirt that can damage internal parts.

- Check for problems: When the feed machine has problems, you need to determine what the specific problem is. For example: it cannot be started or it runs abnormally. If you cannot solve it yourself, you can contact professional technicians.

- Replace worn parts: When severely worn parts are found, they should be replaced in time to avoid causing greater damage.

- The feed machine should be operated according to the instruction manual to avoid damage to the equipment or other unexpected situations caused by improper operation.

Conclusion

Lima has been producing poultry feed machines and poultry feed production lines for many years and has rich experience. We will provide customers with very good services and help you produce feed pellets at home. If you need a feed machine, please contact us!